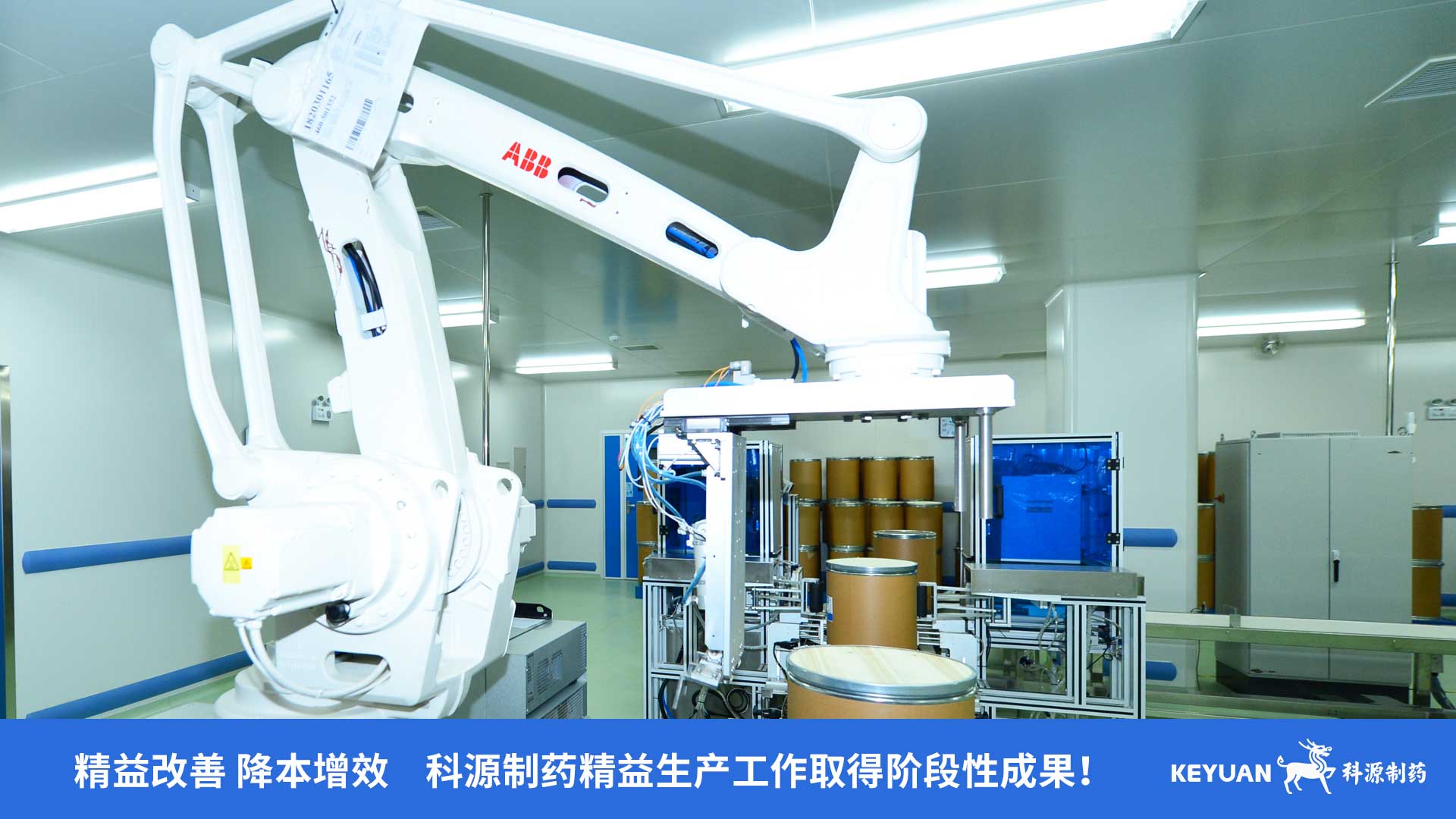

Lean Improvement, Decrease Cost and Improve Efficiency (Issue 1) | Keyuan Pharma's lean production work has achieved periodical results!

Lean production, management first. Since March, Keyuan Pharma (stock code: 301281.SZ) has established a lean promotion committee to create lean awareness among all employees. Under the guidance of the group's lean experts, Keyuan Pharma has implemented the concept of lean digitalization intelligence, and introduced digital intelligence lean value stream analysis and other advanced tools. Keyuan Pharma has achieved significant improvement results in benchmark factories, this is a solid step on the road to achieving quality improvement, cost reduction and efficiency increase.

Under the background of the rapid development of digital intelligence manufacturing industry, lean digitalization, as a deep integration of lean management and digital technology, empowers each other, helps manufacturing companies optimize resource allocation, improve production efficiency, improve operating benefits, and improve customer experience, and is increasingly valued in corporate development.

In order to achieve high-quality development, Keyuan Pharma has listed lean digital intelligence operation management as one of the core concepts of corporate development. In terms of building a lean production system, Keyuan Pharma has conducted in-depth exploration and practice: starting with improving the efficiency of the fourth workshop's production line, relying on lean value stream analysis, and taking subject improvement as a starting point, the factory gradually established a standardized site. Now, Keyuan Pharma has achieved period results in the benchmark factory.

Identify bottleneck processes and optimize production processes

At the beginning of the construction of the lean benchmark production line, Keyuan Pharma first identified the bottleneck process through the value stream to optimize the balance of the production line. The value stream map can describe the material flow, information flow and key indicator parameters, accurately identify the bottleneck process that affects production efficiency, so that the factory take corresponding improvement measures to reduce waste in the production process.

Pull production principle to reduce inventory backlog

Keyuan Pharma implements the pull production principle to achieve more efficient production management. Pull production means that production is carried out only when customer demand arises, which helps to reduce inventory and waste and improve the ability to respond to market changes. In this way, Keyuan Pharma ensures that production activities are closely linked to market demand and thus reduces unnecessary inventory backlogs.

Total production maintenance, improve production stability and efficiency

In the process of promoting lean production, Ke yuan Pharma implemented total production maintenance (TPM), reducing equipment failures and improving production stability and efficiency through daily self-maintenance, professional maintenance and preventive maintenance. In addition, the factory actively carried out subject improvement activities, encouraged employees to put forward improvement suggestions, and promoted bit by bit improvement and continuous improvement.

Focus on talent training and stimulate endogenous motivation

Lean talent cultivation is the key to the success of lean production. In terms of talent training, Keyuan Pharma cultivates employees' lean production awareness, knowledge and skills through systematic training and practical opportunities to ensure that every employee can play a role in the lean production system.

So far, Keyuan Pharma has built an efficient and stable lean production system in the benchmark factory, trained a lean management team with strong awareness, sufficient experience and high level, and effectively achieved the improvement goal of reducing costs and increasing efficiency.

In the future, Keyuan Pharma will continue to fully implement the lean production concept, give full play to the advantages of lean digital intelligence operation and management through lean guidance and digital empowerment, improve the environment, optimize processes, improve efficiency and reduce costs, and provide a strong source of power for the high-quality development.